Xirmooyinka tuubooyinka gacmaha dhoobada leh ayaa lagu dabaqay warshadaha macdanta

Ku saabsan xirmooyinka tuubooyinka gacmaha dhoobada

Dhexroorka weyn ee gacmaha dhoobada dhoobada ayaa had iyo jeer dhibaato weyn ku ah soosaarayaasha tuubada dhoobada tan iyo markii ay aad u adagtahay in la xakameeyo heerka qallooca ee gacmo-gacmeedka dhoobada ka dib marka la gooyo. Ma muujin doono oo kaliya awoodda wax soo saarka shirkadda, laakiin tignoolajiyada shirkadda.Waqtigan xaadirka ah, warshadeena waxay leedahay labadaba faa'iidooyin kuwaas oo xidha tas-hiilaadka tuubooyinka dhoobada ee adkaysiga u leh iyo tignoolajiyada.

Waxaan la kulannay qaar ka mid ah dhibaatooyinka dabcan marka aan soo saarno gacmo-gacmeedyada dhoobada waxaanan xalinay dhammaan dhibaatooyinka ka dib dadaalka cilmi-baarista iyo injineernimada dadka. weyn oo culus .

Sintering sida tuubada dhoobada oo dhan ama shaambo dhoobada ah, ka dibna ku soo ururi tuubada birta ah ama tuubada birta ah ee birta ah ee leh xabagta epoxy-adkeysiga u adkaysata heerkulka sare.Dhuumaha gacmaha dhoobada safan ayaa wax badan ka codsatay warshadaha macdanta, sida tuubada slurry macdanta, macdanta boodhka saarida tuubooyinka, tuubada gudbinta slag macdanta, xusullada iyo tuubooyinka T.

Noocaan tubooyinka dhoobada leh ee dhoobada leh waxay ka kooban yihiin saddex qaybood (tuubo bir ah + dhejisyo + dhoobada dhoobada ah), tuubada birta waxay ka samaysan tahay tuubo bir kaarboon ah oo aan fiicnayn.Duubyada dhoobada ah waa 95% alumina sare, iyo isku-xidhku waa xabagta epoxy heerkulka sare ilaa 350oC. Tuubooyinka noocan oo kale ah waxay ku habboon yihiin gaadiidka budada iyada oo aan dufanku dhicin ama gabow ka hooseeya 350oC muddo dheer.Muddada nolosha adeeggu waa 4 ilaa 5 jeer ka badan birta caadiga ah.

Xirmooyinka tuubooyinka gacmaha dhoobada leh ee daboolan baaxadda codsiga

Tuubooyinkan loo isticmaalo Nidaamyada Pneumatic iyo Hydraulic Systems waxay la ildaran yihiin daal aad u sarreeya, simbiriirixan sare iyo saameyn sare, gaar ahaan xusullada.Waxaan sidoo kale naqshadeyn karnaa xirmooyinka tuubooyinka gaarka ah si aan ula kulanno codsiyada shaqada ee kala duwan.

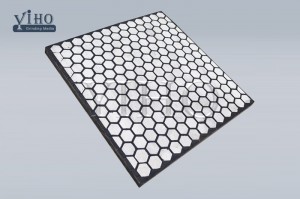

Dharka dhoobada ah ee Shayga & Sawirada

-92% aluminium

-95% aluminium

-99% aluminium

-RBSiC Silikon carbide

-ZTA liner

| Qaybta | HC92 | HC95 | HCT95 | HC99 | HC-ZTA |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% |

| ZrO2 | / | / | / | / | ≥21% |

| Cufnaanta (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 |

| HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 |

| Rock Hardness HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 |

| Laacida Xoog MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 |

| Awood cadaadis MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 |

| Adag jabka (KIc MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 |

| Xidho mugga (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 |