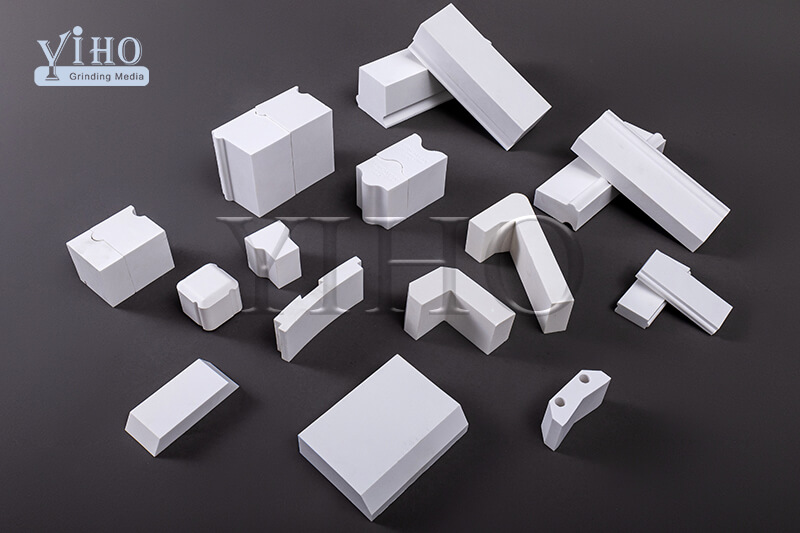

Tuubooyinka dhoobada iyo qaybaha gaarka ah

Qaab dhismeedka Alaabta:

| Qaybta | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Cufnaanta | 3.50g/sm3 | 3.60g/cm3 | 3.65g/cm3 | 3.70g/cm3 | 3.83g/cm3 | 4.10g/cm3 | 5.90g/cm3 |

| HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Laacida Xoog MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Awood cadaadis MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Jab adag Kic MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Xidho mugga | ≤0.28cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

Tusaalooyinka Isticmaalka

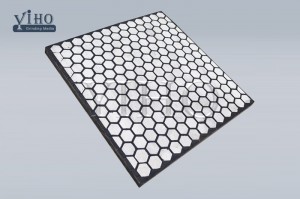

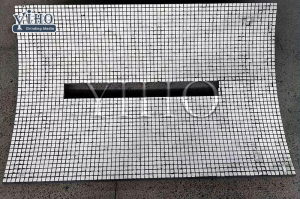

Xusuusin: Waxaan samayn karnaa tile alumina xirashada sida waafaqsan shuruudahaaga.

Astaamaha

Adag sare

Adkeydka Rockwell ee ceramics-ka sare ee alumina waa ilaa HRA80-90 kaas oo ah kan labaad ee kaliya dheeman oo aad uga badan birta aan xirneyn

Iska caabbinta xirashada heer sare ah

Iska caabbinta xirashada ee ceramics sare ee alumina waa 266 jeer oo ka mid ah birta manganese iyo 171.5 jeer oo ka mid ah birta birta ah ee chromium. Sida laga soo xigtay baaritaankeena & dabagalka macaamiisha, nolosha adeegga qalabka ayaa lagu dheerayn karaa waqtiyo 10 oo isku mid ah. xaaladaha shaqada.

Iska caabin daxalka

dhoobada alumina sare waa oksaydhyo inorganic leh qaab-dhismeedka kelli aad u deggan oo aan lahayn daxalka electrochemical, sidaas darteed waxay iska caabin karaan nabaad guurka ee acid, alkali, milix xalalka iyo organic Solvents.

Heerarka kuleyliyaha

Heerkulka shaqada ee dhoobada aluminium sare waxay noqon kartaa ilaa 1400 ℃.

Is-jiid wanaagsan

Ceramics-ka sare ee alumina waxay leeyihiin sifooyinka is-dheellitirka iyo is-dheellitirnaanta, qallafsanaantu waa 1/6 oo keliya tan tuubooyinka birta sidaas darteed qulqulka qulqulka ayaa ka yar.

Miisaan fudud

Cufnaanta ceramics-ka sare ee alumina waxay ku saabsan tahay 3.6g/cm3, taas oo ah kala badh ka mid ah birta, sidaas darteed way fududahay dhismaha iyo rakibidda

Xiro xalalka aanu bixino

Tani waa nidaam adag. Injineeradayadu waxay fahmaan dhibaatooyinka xidhashada oo ay sheegaan

xalal aad ku buuxin karto jawiga shaqada.Guryaha alaabta, dulqaadka, fidsanaanta, hababka lifaaqa, iyo kharashyada agabka ayaa dhamaantood lagu tixgaliyaa xidhashada

Codsiyada

• Burburka/Hoppers

Cones-ka kala saarta

• Kala-saarayaasha duufaanta

• xusulada

• Guryaha Fanka & Daabka

• Tuubooyinka safan

• Duubista

• Xiro Panels

Suuqyada

• Korontada Dhuxusha laga shido

• Maaraynta Walaxda Xun

• Habaynta Kiimikada

• Habaynta cuntada

• Wax-soo-saarka Birta/ Birta

• Ka-hortagga macdanta

• Gaadhida budada/Adadag badan

• Samaynta Saxarka & Warqadaha

Burburinta & Shiididda