Xiro Injineernimada Matrix Ceramic

Ku saabsan Xiro Ceramic Matrix

Abrasion had iyo jeer waa mid aan laga maarmi karin habaynta iyo rarida agabka badan.Qulqulka walxaha dhacaya wuxuu keenaa saameyn xoog leh gaar ahaan.Waxaan macaamiisheena ku siineynaa xalalka ugu fiican ee tayada sare leh ee dharka dhoobada ah (oo leh / aan lahayn saxan bir ah iyo boodh), si loo gaaro natiijo wanaagsan oo lagu kordhinayo caabbinta saameynta iyo yaraynta xajinta iyo qaylada.

Xirmooyinka Weriyeyaasha Ceramic Conveyor Wear waxay si weyn u dhimi doonaan kharashaadkaaga shaqo marka la barbar dhigo wax kasta oo dahaarka ah.

Yiho waxay soo saartaa noocyo kala duwan oo xirashada xirashada gaadiidka qaada oo leh ikhtiyaaro iyo cabbirro laga dooran karo.Loogu talagalay in lagu qabto codsi kasta oo adag macdan qodista dhagaxa.Abrasion u adkaysta, modular, maro-xiran sare ilaa suunka suunka, iyo meelaha saamaynta qashinka.

Xidho Astaamaha Matrix Ceramic

* Iska caabin aad u sarreeya

* Isku xidhayaasha is-jiidhka hoose

*Qaylada dhimista

* montage fudud oo degdeg ah

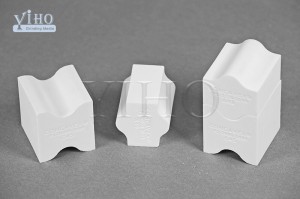

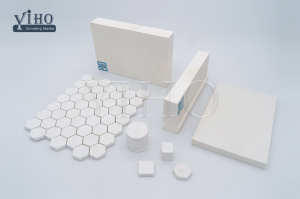

Nooca dhoobada

Silinder| Hex Tile | Laydi leh |Square | Cube

92%, 95%, 99% Al2O3, ZTA, RBSIC Silicon Carbide

Xogta Farsamada:

| Qaybta | HC92 | HC95 | HCT95 | HC99 | HC-ZTA |

| Al2O3 | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% |

| ZrO2 | / | / | / | / | ≥21% |

| Cufnaanta (g/cm3 ) | >3.60 | >3.65g | >3.70 | >3.83 | >4.10 |

| HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 |

| Rock Hardness HRA | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 |

| Laacida Xoog MPa | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 |

| Awood cadaadis MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 |

| Adag jabka (KIc MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 |

| Xidho mugga (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 | ≤0.05 |

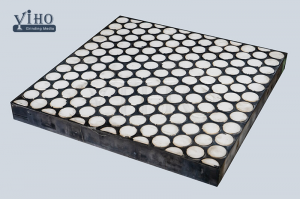

Nooca Wear Matrix

* Matrix dhoobada caagga ah

* Matrix dhoobada caagga ah ee ay taageerto birta

Cabbirka Matrix Wear Ceramic

Joogto ah&la habeeyey,

Max L800*W800mm

Warshadaha waxaa ku jira Matrix Wear Ceramic

• Isku geyn

• Daamur

• Sibidhka

• Kiimikada

• Dhuxusha oo la shido

• Awood

• Dhuxusha

• Habaynta

• Burburinta

• Bacriminta

• fiberglass

• Dambaska duula

• Cunto

• Habaynta

• Aasaaska

• Frac Ciid

• Dhalo & Frit

• Hadhuudh

• Gypsum

• Bir & Birta

• Macdanta

• Habaynta

• Macdanta

• Ciidda Saliidda

• Saliidda & Gaaska

• Kiimikada batroolka

• Bootashka

• Saxarka & Warqada

• Quarry

Dib u warshadaynta

• Saqafka

• Qalabka

• Ciid & Jay

• Sonkor

• Biyaha wasakhda ah

• Walxaha budada/Bulk

• Wax ka qabashada

• Suuqyada loo adeego

• La heli karo

Codsiyada Matrix Wear Ceramic

• Khadadka Dambaska

• Xadhkaha Miinooyinka Kubadda

• Qalabyada Quudinta Jilif

• Xakamaynta jilif

• Suxulada Dhabarka ah

• Clinker Hoppers

• Weelasha dhuxusha

Gudbinta Kala-guurka

• Duufaanno

• Qalab Qabyo ah

• Xadhkaha boodhka aruuriya

• Taageeraha daalka

• Guryaha

• Ka bixida Dhuumaha

• Quudi jeexyada

• Suxullada Dhabarka ah ee fidsan

• Khadadka xoqida gaaska

• Xakamaynta Shidaalka Hog

• Guryaha Taageerada Aqoonsiga

• Guryaha Jidhka ee Mill

• Bunkers

• Jirrada pulverizer

Kala soocida Pulverizer

Cones

• Soo daynta pulverizer

• Valves

• Dhagaxa gidaarka sariirta

• Silos & Bunkers

• Kala-guurka

• Baabuurka Xamuulka iyo Tareenka

• Qashinka Dhuxusha

• Sanduuqyada dhaqda

• Wennberg Screws