Isku-dhafka Xargaha dhoobada dhoobada ah

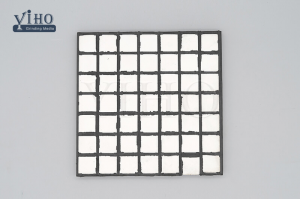

KU SAABSAN Matrix Ceramic Rubber Liner Hybrid

Ku biirista iyadoo la adeegsanayo hannaan gaar ah, Hybrid Liner wuxuu isku daraa laba shay oo liner ah iyo sifooyinkooda wanaagsan.Guduhu wuxuu ka samaysan yahay polyurethane wuxuuna ilaaliyaa addimada haraaga ah iyo qaababka lafaha iyada oo ay ugu wacan tahay sifooyinka soo jiidashada shoogga.Isla mar ahaantaana, waxay hubisaa qaybinta cadaadiska ugu wanaagsan ee dhammaan addimada haraaga ah, labadaba jiilka firfircoon ee faakuumka.Dusha sare ee xadhkaha iyo faakuumka isku dhafan waxay ka samaysan yihiin silikoon, oo lagu caddeeyey isticmaalka maalinlaha ah iyada oo ay ugu wacan tahay awooddeeda.Tani waxay si gaar ah muhiim u tahay marka faakuumka faakuumka lagu duubo godka gudaha si loo abuuro shaabad aan hawo lahayn oo nidaamka.

Codsiga Matrix Ceramic Liner Hybrid Liner

Mawduuca ciribtirka ee ku saabsan dahaarka caagga ah, weedhahan soo socda waa in la tixgeliyaa.

1- Waxaa jira laba nooc oo nabar-ku-soo-bax ah oo laga yaabo inuu la kulmo, xannibaad iyo sibraar.

2- Naaxinta wax-ka-qabashada waxay dhacdaa marka qaybuhu ay ku dhacaan dusha sare ee caagga (ama meel kasta oo kale).

3- Naaxinta simbiriirixashadu waxay dhacdaa marka dusha kale uu ku dul simbiro caagga.

4-Dhammaan kiis kasta nabar-goynta waxaa laga filan karaa inay isku darsamaan carqaladayn iyo simbiriirixid.

5- Nabar-goynta ugu badan waxay ku dhacdaa tubbada ciidda, iyo meel kasta oo dib loo soo celiyo.

6- Inta lagu guda jiro is-hortaagga, qaybo ka mid ah waxay ku dhacaan dusha sare iyo wixii cadaadis ah ee la soo saaro si siman ayaa loo qaybiyaa haddii caaggu si fudud u soo saaro, gaar ahaan marka qaybaha ay ku dhuftaan xagal 90 ° dusha sare ah.

Alaabta dhoobada ah (Alumina + falcelinta ku xidhan Silicon Carbide Tiles)

| Qaybta | 92% Al2O3 | 95% Al2O3 |

| ZrO2 | / | / |

| Cufnaanta(gr/cm3) | >3.60 | >3.65g |

| HV 20 | ≥950 | ≥1000 |

| Rock Hardness HRA | ≥82 | ≥85 |

| Laacida Xoog MPa | ≥220 | ≥250 |

| Awood cadaadis MPa | ≥1050 | ≥1300 |

| Adag jabka (KIc MPam 1/2) | ≥3.7 | ≥3.8 |

| Xidho mugga (cm3) | ≤0.25 | ≤0.20 |

| Silicon CarbideXogta(RBSiC) | ||

| Tusmada | Qiimaha | Natiijada tijaabada |

| Sida | / | ≧90 |

| Heerkulka | ℃ | 1380 |

| Cufnaanta Gaarka ah | g/cm3 | ≧3.02 |

| Porosity furan | % | 20.1 |

| Hababka barti: | Gpa | 330Gpa (20 ℃) 300Gpa(1200 ℃) |

| Adagnimada Moh | / | 9.6 |

| Xoog laabashada | Mpa | 250 (20 ℃) / 280 (1200 ℃) |

| Xoogga Isku-buufinta | Mpa | 1150 |

| Isku-dubbaridka ballaadhinta kulaylka: | / | 4.5K^ (-3)*10^(-5) |

| Isku-dhafka kuleylka kuleylka: | W/mk | 45 (1200 ℃) |

| Acid Alkaline-caddayn | / | Aad u fiican |