Xiro dahaarka u adkaysta duufaanta ee laga sameeyay Alumina

Sharaxaad faahfaahsan

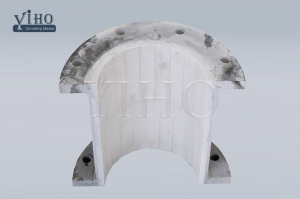

Jirka ugu weyn ee duufaantu waxa uu ka kooban yahay wax yareeya ama koofiyad qaabaysan oo ka samaysan dhexroor weyn ilaa mid ka yar hoos dhererkeeda.

Xidho xalalka iska caabinta ee duufaanada

Maadaama walxaha ku kala go'ay duufaantu ay yihiin kuwo aad u xoqaya, waxaa muhiim ah in la helo dahaarka duufaanka kaas oo u taagan adkeynta shaqada.Ultra High Purity Alumina waxaa loo isticmaali karaa in lagu kordhiyo nolosha shaqada duufaanka iyo waxqabadka waxaana loo qaabeyn karaa qaab ku habboon dhammaan joomatariyada;Laga soo bilaabo shaqada tuubada ee u horseedaysa meesha laga soo galo, raadiyaha vortex-ka iyo meesha ugu sarreysa, ilaa wadnaha qoobka ee duufaanta.

Qaybaha duufaanta ee Caadi ahaan ku xidhan Xidhashada

Waxa jira qaybo badan oo ku dhex jira shirka duufaannada kuwaas oo ay ku xiran yihiin xaaladaha xidhmo sare.Taylor Ceramic Engineering waxa ay ku siin kartaa qaar badan oo ka mid ah agabka xidhashada u adkaysta si loo kordhiyo nolosha qaybaha.Qaybaha aan sida caadiga ah u bixino waxaa ka mid ah:

Xadhkaha cylindrical & Yaraynta

· Meelo laga galo

· Dukaamada

· Caano

Gelida

Qaybta Sare, Dhexe & Hoose ee Koontada

Soo-helayaasha Vortex

Xaqiiq ahaan dusha kasta oo la gashado!

Xiro Foomamka Dahaarka Iska caabinta

Farsamooyinka dahaarka u adkeysiga xirashada ee kala duwan ayaa la isticmaali karaa;Laga soo bilaabo gelinta monolithic ilaa qaybaha dhoobada.

Qaybaha monolithic

YIHO waxay si gaar ah u taagan tahay inay awood u yeelato inay soo saarto qaabab monolithic yar iyo weyn leh muddo gaaban gudaheed.Qaybahan waxa loo samayn karaa caado si ay ugu habboonaato shuruudahaaga saxda ah.

Qaybaha monolithic ayaa faa'iido u leh in ay aad u dhaqso badan yihiin in la rakibo, sidaas darteed hoos u dhigista wakhtiga.

Qaybaha tiirarka

Sababtoo ah inta badan sagxadaha la xidhiidha shirka duufaantu waa qaloocan yihiin, Taylor Ceramic Engineering wuxuu awoodaa inuu farsameeyo dusiyooyin waafaqsan qaabka saxda ah ee loo baahan yahay.

Duubabka fidsan ee sagxadaha qalloocan waxay inta badan ka tagaan dabaqyo taxane ah oo ku wareegsan dusha sare ee duufaanta.Tani kaliya kama joojinayso socodka walxaha laakiin waxay kordhisaa xidhashada dusha sare ee tiirarka sidaas awgeedna waxay yaraynaysaa nolosha qalabka.Si kastaba ha noqotee, isticmaalka foornada qalloocan ee injineernimada ee waafaqsan qaabka loo baahan yahay waxay yaraynaysaa joojinta waxayna kordhisaa socodka walxaha iyo markaa waxtarka qalabka.

| Qaybta | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Cufnaanta | ≥3.50g/cm3 | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 | ≥3.83g/cm3 | ≥4.10g/cm3 | ≥5.90g/cm3 |

| Nuugista Biyaha | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% |

| HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Laacida Xoog MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Awood cadaadis MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Jab adag Kic MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Xidho mugga | ≤0.28cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |